By Bob Reece

Round rubber and spandex are two members in the vast tide of synthetic materials that have washed over the fly tying world in recent years.

They have both been used to create numerous surface and subsurface patterns. However, I would argue that one is better suited for the world above while the other thrives below.

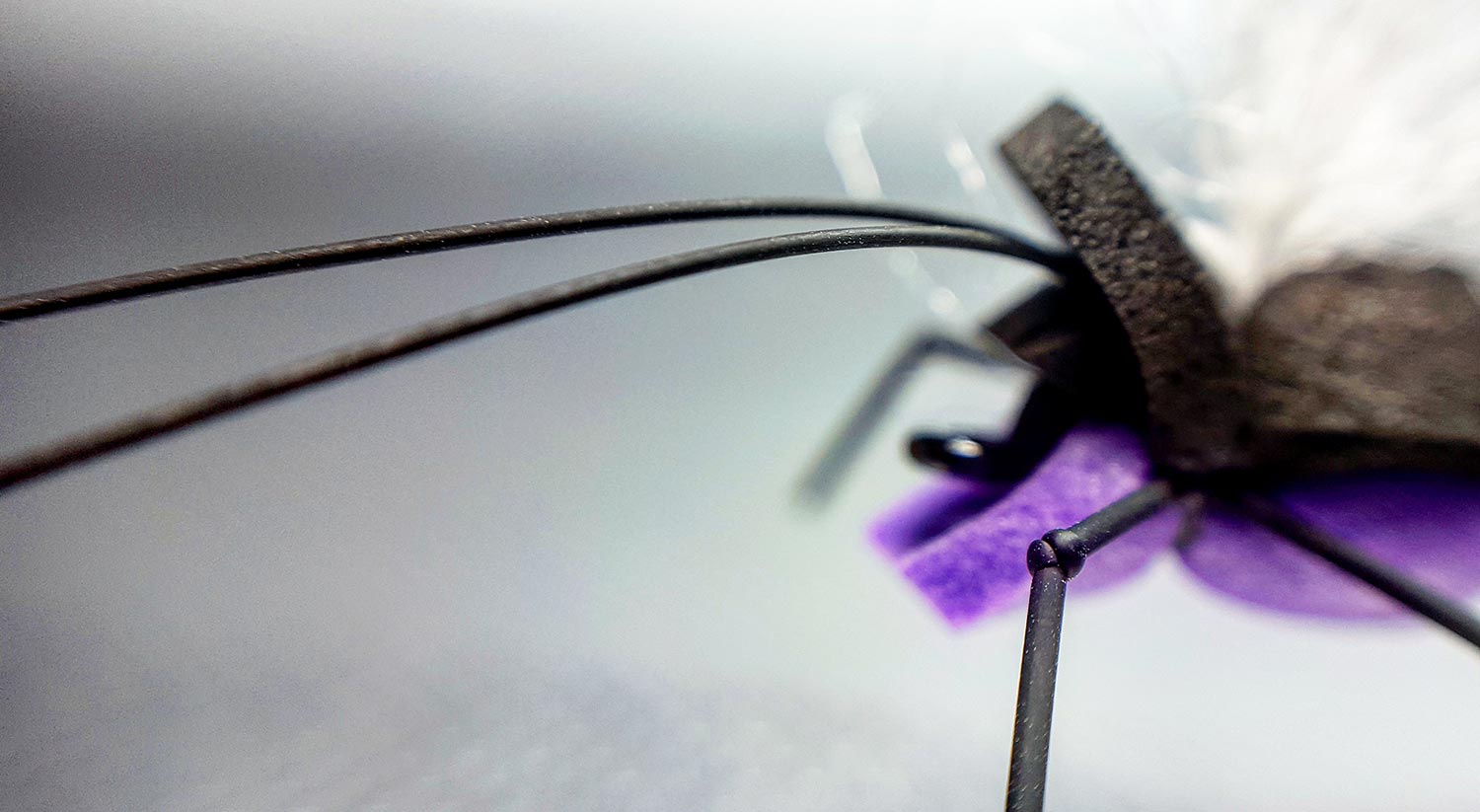

Round rubber comes in a wide array of colors and sizes. While this material has been used on numerous subsurface patterns, I would argue that it’s most effectively put to use on the water’s surface. In comparison to the structural makeup of spandex, round rubber is a rigid material. Due to this comparatively stiff makeup, its motion is produced at a longer wave length. This trait is beneficial in the creation of appendages for terrestrial patterns both large and small. The legs and antennae of terrestrial insects are typically much longer than those of aquatic insects. As a result, those appendages often extend significant distances away from the body and the rigidity of round rubber is ideal for imitating this trait. Its structure allows for the creation of longer hopper, beetle, spider and other terrestrial appendages that will maintain their dimension while still providing movement. Conveniently, the rounded shape of medium round rubber also results in a more consistent and controllable knot. These knots can be used to imitate prominent leg joints. This consistency eases the process of creating the approximate right angle in these legs, resulting in a bent leg look that more effectively imitates the natural.

Round rubber comes in a wide array of colors and sizes. While this material has been used on numerous subsurface patterns, I would argue that it’s most effectively put to use on the water’s surface. In comparison to the structural makeup of spandex, round rubber is a rigid material. Due to this comparatively stiff makeup, its motion is produced at a longer wave length. This trait is beneficial in the creation of appendages for terrestrial patterns both large and small. The legs and antennae of terrestrial insects are typically much longer than those of aquatic insects. As a result, those appendages often extend significant distances away from the body and the rigidity of round rubber is ideal for imitating this trait. Its structure allows for the creation of longer hopper, beetle, spider and other terrestrial appendages that will maintain their dimension while still providing movement. Conveniently, the rounded shape of medium round rubber also results in a more consistent and controllable knot. These knots can be used to imitate prominent leg joints. This consistency eases the process of creating the approximate right angle in these legs, resulting in a bent leg look that more effectively imitates the natural.

Moving below the surface of the water, I believe spandex gains the upper hand. The same “weaknesses” that it displays for its uses above give it the upper hand below. Aquatic insects, especially those in moving water, sport much shorter and flattened limbs. This flattened trait creates a more fluid dynamic profile resulting in reduced drag from currents and easier movement through their liquid world. Since the joints of the legs are much closer together, their movement takes on a much wigglier and crawling appearance. On top of this, there is often a hint of translucence that can be seen in their appendages. Spandex displays all of these traits. Its flimsy structure allows it to come to life with supple movement in imitation of legs, tails and antennae. Its physical shape, resulting from its production, is flattened. Because of this thinner profile, most of the colors of spandex material are also translucent. In recent years this product has been produced in a wide range of widths, allowing it to be used for a much wider spectrum of pattern sizes and mimicked appendages.

Moving below the surface of the water, I believe spandex gains the upper hand. The same “weaknesses” that it displays for its uses above give it the upper hand below. Aquatic insects, especially those in moving water, sport much shorter and flattened limbs. This flattened trait creates a more fluid dynamic profile resulting in reduced drag from currents and easier movement through their liquid world. Since the joints of the legs are much closer together, their movement takes on a much wigglier and crawling appearance. On top of this, there is often a hint of translucence that can be seen in their appendages. Spandex displays all of these traits. Its flimsy structure allows it to come to life with supple movement in imitation of legs, tails and antennae. Its physical shape, resulting from its production, is flattened. Because of this thinner profile, most of the colors of spandex material are also translucent. In recent years this product has been produced in a wide range of widths, allowing it to be used for a much wider spectrum of pattern sizes and mimicked appendages.

Both of these synthetic materials are excellent additions to many fly designs. Their construction can be used to add both movement and aesthetic accuracy to pattern profiles. Considering their strengths can lead to the creation of flies that are more effectively suited for their applications.

To follow Bob Reece on Instagram click on the link below.

https://www.instagram.com/thin_air_angler/

For how-to tying videos, rigging tips and more check out the link below.

https://www.facebook.com/ThinAirAngler/

To purchase custom made tying material kits for Bob Reece’s patterns, click on the link below.

Bob Reece Gink & Gasoline www.ginkandgasoline.com hookups@ginkandgasoline.com Sign Up For Our Weekly Newsletter!

I just glanced at it. I thought it said rub her above and below.

Ha ha ha, I asked, but Louis said that wouldn’t be a viable topic for this blog.

Food for thought. Haven’t had a chance to use spandex much yet, will have to give it a try on some nymphs, maybe stoneflies.

Get after it. It’s a lot of fun to use!

Rubber may be good for surface flies but I have too many old flies that have brittle and broken rubber legs and I always use the silicone legs now..

Interesting, in my experience the silicone legs degrade quicker than the rubber ones.