A few months ago, I had the pleasure of touring the Thomas & Thomas factory. During the walk through, I found myself getting emotional and I regularly had to fight back the tears welling up in my eyes. At first, I didn’t understand why I was feeling these sad emotions, and then it hit me squarely in the chest, and it became crystal clear. The sadness I was feeling was coming from all the past memories of my peers badmouthing and writing off the Thomas & Thomas brand. It made me think about all the great fly fishermen out there not fishing T&T rods anymore, and it wasn’t because the T&T rods lacked performance or quality, it was rather that T&T no longer carried that “popular appeal” in the eyes of the everyday angler. Walking around with watery eyes, I heard the negative voices saying comments like, “Who is T&T, haven’t they closed the doors?” or “The T&T craftsmanship isn’t what it used to be, and I’ve been burned one too many times by their customer service.” What bothered me most, is all of those negative comments that I’d heard over the years, clearly didn’t match up with what I was seeing in person at the T&T factory. There was an overwhelming pride that was genuinely displayed on the eyes of every single T&T employee. And I thought to myself, “If only the naysayers could be walking in my footsteps right now, they’d understand the real truth about this fly rod company’s journey, and the beauty and uniqueness of its products.”

There’s no question that Thomas & Thomas has lived through some tough years in the past, and many of its loyal customers have suffered from the turmoil created by the company changing hands. That being said, the company and staff deeply regret the tarnish that’s been attached to the T&T name in recent years. Every day that goes by, the T&T staff is working hard to make things right moving forward, and they’re doing it by winning back one fly angler at a time. One thing everybody in the fly fishing industry needs to understand about T&T, is they’ve never changed the quality of their craftsmanship or the philosophy of how they design and manufacture fly rods. And I think it’s equally important that the T&T history and story be told, that way each and every fly fisherman can be educated on the company’s roots, what caused the troubled years at T&T, and where the company stands today. I’m honored to be associated with Thomas & Thomas, and I’m proud of the solid group of employees (all passionate fly fishermen) that are bringing T&T back to the glory days.

Thomas & Thomas Orgins

The story of Thomas & Thomas resonates with fly angler’s around the world. Two fly fishing enthusiasts married two sisters. The sisters had a relative that built bamboo rods. He trained the brother-in-laws to build them, and by accident, they both found their vocation. It was a case of pure serendipity. Within a short space of time, Tom Dorsey and Tom Maxwell had rented a cabin/workshop on the banks of one of Pennsylvania’s famous limestone creeks, and were building bamboo rods to fund their trout fishing lifestyles. The year was 1969 and Thomas & Thomas Rodmakers was born.

Influential anglers of the day, including Vine Marinaro and Ernest Schwiebert heralded the Thomas & Thomas rods as unequalled for their rare combination of casting performance and flawless craftsmanship. With a growing waiting list for rods, Thomas & Thomas searched around for better machinery that could increase their output. The journey took them to a New England auction house, where extensive machinery from the Montague and Sewell-Dunton rodmaking facilities were coming under the hammer. Thomas & Thomas successfully won bids for the historic milling machines, as well as, a huge stash of pre-embargo Tonkin bamboo. But it soon became evident that their finances would not stretch to moving the hefty equipment from Massachusetts to PA. Instead, in 1974, they gathered their young families and moved north.

The T&T Progress

In the mid-1970’s, Tom Dorsey began experimenting with the production of graphite fly rods. Early Thomas & Thomas models were branded as “G” followed by a number denoting their length, then line weight, for example, G8045 – denoting a graphite rod, 8’0″ in length for #4 or #5 lines. The first graphite rod to be given a name was the now legendary Special Dry Fly. It was soon followed by other T&T classics, such as the Trouter, Firehole, Iliaska Speical, Gaspe, and T&T’s first two handed rod, The Gaula. Interestingly, customer anecdotes contained in T&T catalogs from this time express delight at being able to cast an entire fly line with the higher line rated rods, such as the Gaspe. Despite the claims of modern rodmakers, the evolution in graphite fly rods over the last forty years has increased casting distances for most anglers by only small amounts. Early Thomas & Thomas graphite rods were characterized by a simple, understated aesthetic, a carry over of T&T’s bamboo mantra of “form follows function”.

T&T blanks were sanded and clear coated, allowing the graphite fiber to show through and were complemented with subtle, silk guide wraps, milled aluminum reel seats and mortised wood spacers. By the 1980s, Thomas & Thomas was widely viewed in USA fly fishing circles as a national treasure. High profiled anglers of the era waited patiently for their T&T rods, while then President of the USA, Ronald Reagan commissioned T&T to build rods to present to the Prime Minister of Australia and to Prince Charles and Lady Diana on the occasion of the UK’s Royal Wedding. This was the only known Presidential Commissions for fly fishing equipment at the time.

During this time, Thomas & Thomas was both a rodmaking workshop and a fly shop, selling a multitude of products under it’s own brand, as well as, “best in class equipment” from makers, for example Hardy reel, Cortland Lines, Wheatley fly boxes, Barbour jackets and Patagonia clothing. The arrival of the annual Thomas & Thomas catalog brightened the dark winter months for many fly fishermen around the world.

Paradigm Shift

The 1990s marked a paradigm shift for fly fishing in the United States and also for Thomas & Thomas. With more and more American’s enjoying increased leisure time and higher levels of disposable income, the sport moved toward the mainstream. In response, independent specialty fly shops became a feature of more and more towns, a trend further fueled by the success of the movie, A River Runs Through It. Under new ownership, a decision was taken for Thomas & Thomas to place a much greater emphasis on developing a worldwide network of dealers. As part of this process, it was also decided that all future T&T graphite rods would be painted a deep blue, to make them more recognizable on fly shop rod racks.

This is when Thomas & Thomas transitioned from a small, boutique rodmaker to a larger player competing for the hearts and minds of fly fishermen. T&T provided a more dynamic rod offering that included successful rod series such as the Paradigm, LPS, Vector, Helix, Horizon and DH. By the late 1990s, and early 2000s, Thomas & Thomas employed over 35 people in its rod making facility, building as many as 12,000 graphite rods per year. Many of the rods were sold internationally to countries such as the UK, Japan, France, Germany and Scandinavia, where the fly fishing community identified with T&T’s heritage, craftsmanship and Tom Dorsey’s design philosophy.

The T&T Troubled Years

The constant rise of T&T had occurred unabated for over thirty years. It was inevitable that the company’s worldwide reputation would attract acquisitive admirers. In 2005, Thomas & Thomas was acquired by a group of UK investors with designs on creating a supergroup of fly fishing brands. This same group was successful in acquiring Abel reels and Sharpe’s of Aberdeen, and also had their sights firmly fixed on other fly industry notables. Unfortunately, this was where their success ended. With the backdrop of a worldwide financial crisis, it wasn’t long before bank funding terms became more onerous. The group was forced to surrender Able and Sharpe’s, but fought desperately over a protracted period to maintain ownership of Thomas & Thomas.

This uncertainty continued for over five years, and this period of T&T’s history was marked by significantly reduced investment in R&D, and few new product introductions. Severe cash flow restrictions saw the T&T workforce unable to either build or repair rods for extended periods of time, due to a void in graphite and components. Unfortunately, this chaotic situation severely damaged T&T’s goodwill with its dealer channels as orders were late or even worse, unfulfilled. By late 2010, the investment group effectively walked away from Thomas & Thomas, the workforce was laid off, and creditors took possession of the remaining Thomas & Thomas assets. It looked, to all intents and purposes, like a final undignified end for the storied Thomas & Thomas workshop. Thankfully, a couple of its long serving employee’s had other ideas.

The Thomas & Thomas Revival

With the doors locked at T&T, former employee’s Troy Jacques and Trevor Bross made a last ditch attempt to revive the company by calling Alan Gnann, former President of AFFTA (American Fly Fishing Trade Association). Their plea for assistance was met with aggreement, and Gnann began the search to find a purchaser for the Thomas & Thomas name and machinery. To assist, Jacques and Bross provided Gnann with the names of a few Thomas & Thomas customers that they felt may be suitable owners. One of the names on the list was that of Mark Richens of Islamorada, FL, a dedicated fly fisherman, prominent on the Florida Keys saltwater fly fishing scene, and owner of an Atlantic salmon fishing lodge on the Gaspe Peninsular of Quebec. Richens needed no introduction to T&T rods, fishing with them 200 days per year. He agreed to fly up to Massachusetts to take a look at the Thomas & Thomas workshop, its machinery, and meet with ex-employee’s.

Five months later, Richens acquired the Thomas & Thomas workshop on Barton Road along with all of the manufacturing assets. Next, a core crew of vastly experienced rodmakers were recruited and supply lines were established for graphite and other key components. Alongside the ten experienced rod builders that rejoined the company, Tom Dorsey also agreed to return to Thomas & Thomas as rod designer. Thomas & Thomas was back in business, with production of rods re-commencing in August of 2010. Once again, the company was small, independent and owned and managed by true fly fishermen. All of which were motivated by nothing more than the desire to produce fine fly rods.

Nearly fifty years to go full circle, and presently, Thomas & Thomas is profitable, and stronger than it’s been in decades. There’s no question the company is now in good management hands, that it once again has the resources to push R&D, and lastly, that it carries the company wide synergy needed to uphold the highest levels of customer service and product quality. It’s time to bury the negatives of the past and to start spreading the positive word that Thomas & Thomas is strong and here to stay.

Below are a series of Questions and Answers that I had the privilege and honor of asking Tom Dorsey and Mark Richens when I toured the T&T workshop.

My goal and purpose for doing so, was to educate fly anglers on T&T’s high quality of craftsmanship, explain T&T’s design philosophy, and showcase some of the unique details found on T&T rods that most anglers are unaware of.

‘On Rod Design’

Kent: Like most fly fishermen, I’m fascinated by the process of fly rod design. Tom, it is well known that you have been infatuated by the subject for your entire career. How do you arrive at your signature tapers?

Tom: As I’ve said before, rod designing is more aligned with the culinary arts than with science. Make a first try, taste the soup, add or omit some spice, taste again and so on. The length of the process depends upon how high one raises the bar, and one’s level of satisfaction with the results. Haute cuisine or ordinary fare? It’s the rod designer’s goal and inspiration that surfaces in a fly rod.

Mark: You can’t overstate the importance of experience in rod design. Thomas & Thomas has been involved with graphite since it’s emergence as a rod building material, and we have a vast data bank of tapers and patterns. They exist both in Tom’s head and electronically on our computers. It gives us a starting point that somebody entering the field fresh, just wouldn’t have. It’s a huge advantage and enables us to test samples of new materials constantly, and quickly assess whether or not they offer tangible improvements.

‘On the Graphite Blank’

Kent: We’ve spent a lot of time today watching how you create your graphite blanks from scratch. I’m sure a lot of people assume that a sophisticated machine spits them out all day long but that is not the case. With the tacking, rolling, wrapping, baking, sanding, painting and ferruling they seem enormously time consuming and labor intensive to make. Many rod brands get all or a significant percentage of their rod blanks from overseas. Why do you think it’s important to make 100% of your own?

Tom: If you think these blanks are time consuming and labor intensive, just wait till we get to the bamboo department.

Mark: Firstly, it’s who we are and what we do, we’re rod makers. Secondly, we have the peace of mind knowing that the graphite we’re using is the one that was specified for a given design, and that we’ve stored it at the right temperature and not exceeded it’s shelf life. So there’s a quality control benefit as well. Thirdly, it means we can experiment with new designs on a continual basis, in house, rather than having to fly to the Far East and design a rod series in a week or two. Finally, because we roll our own, we are able to repair any fly rod we offer for many, many years in to the future. People are sentimental about their fly rods. They don’t always want the latest and greatest. If a mishap occurs, they want to know they can get their rod repaired, not replaced with a newer version that is ‘similar’.

‘On Reel Seats’

Kent: I’m a big Fan of the T&T reel seats, for their functionality and simplicity. Can you tell me more about them?

Tom: I’ve personally designed every reel seat we’ve ever had, starting of course with the nickel silver seats we use on our bamboo rods. For a long time, we made every one of them in house, but now we have the milled aluminum seats we use on our graphite rods made for us by local machine shops here in New England. My philosophy on rod design has always been that form follows function, and our reel seats exemplify this. In recent years, we have reduced weight by removing it from the inside but we have resisted the temptation to cut away integral sections of the reel seat like other brands. We like the classic look and it does not make sense to create nooks and crannies where dirt or salt can accumulate.

Mark: My favorite part of our reel seats are the Thomas & Thomas roll stamp on the slide band. Our suppliers would much rather lazer engrave than roll stamp. I’m sure it costs us more to do it this way, but we use the original roll stamp from the early T&T years, because it’s a nod to our roots, and a daily reminder of the bar that Tom and Tom originally set for the company in terms of quality and detail.

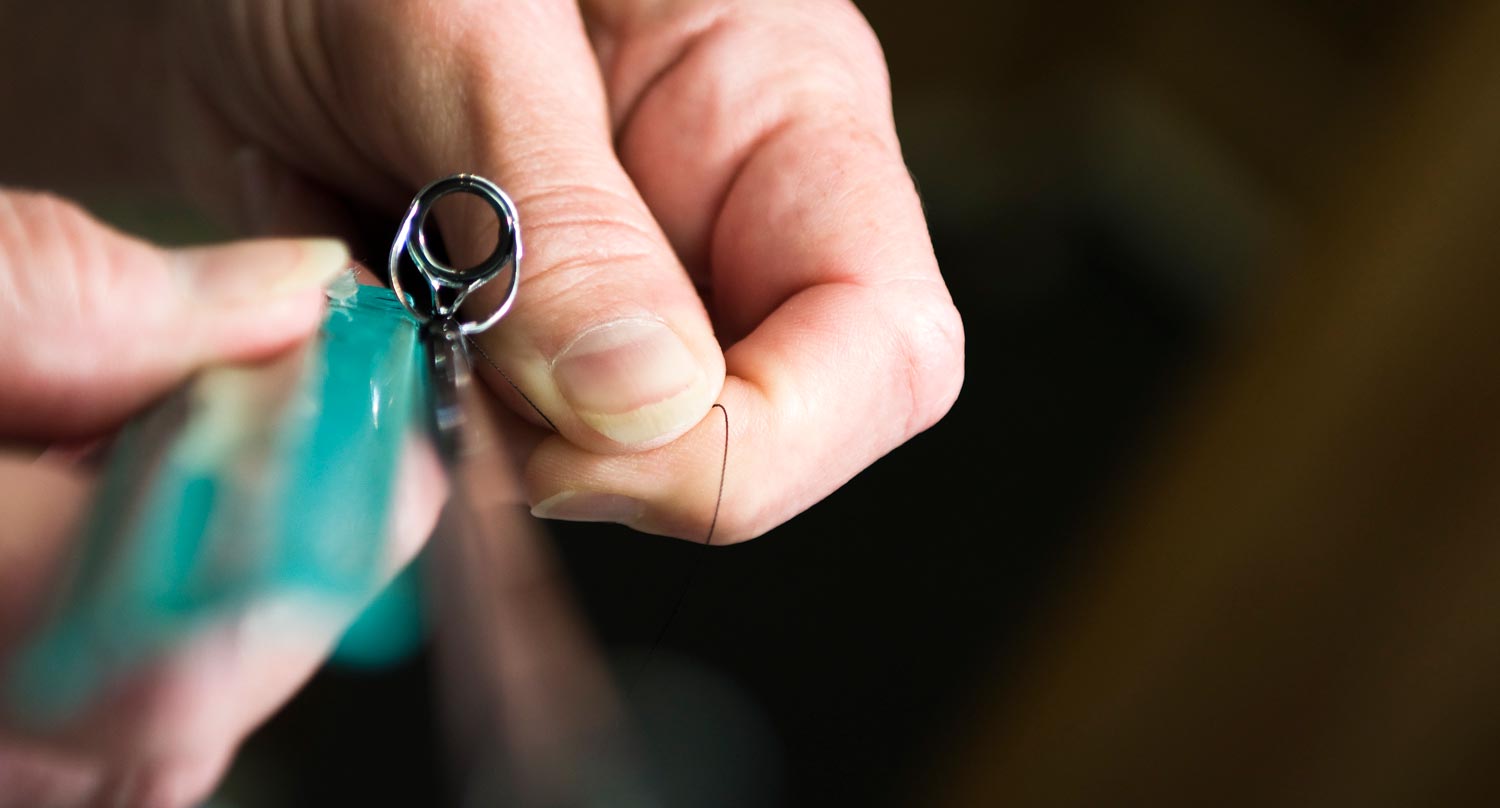

‘On Guides’

Kent: You guys do things differently than a lot of other rodmakers when it comes to rod guides. I’ve noticed that you space them differently, occasionally have one rod guide less, and that you almost always reverse the stripping guides. I’d like for Tom to explain the reasoning behind this.

Tom: In a nutshell, due to the their weight, and hence, the undesirable inertial disturbance they impart, guides are a necessary evil on a fly rod. Take any good fly rod blank and without casting it, just wiggle it. Then slide a 1/8 oz. sinker over the tip and wiggle it again, and behold the difference. Towards the tip of the rod, the effect is enormous, less so as we move the weight toward the butt of the rod. This illustrates an obvious phenomenon; inattentive guide placement (or in fact too many guides) can hinder the potential of the rod. I think about these things a lot, and then I experiment. In the case of guides, I found that using one less than the norm had no negative impact on the ability to control the cast and shoot line.

Mark: You may have noticed Kent that we’ve upgraded the guides across our entire rod range in the last couple of years to Titanium silicon carbide stripping guides and either Universal Snake Brand or REC snake guides. These rod guides cost much more than what we were using before, and what most other production rod companies use. They coast four or five times the price in some cases. Even custom rod builders charge an upgrade to have these guides on a rod. On Thomas & Thomas fly rods, however, they now come standard. Why? Because they are better and by experimenting, we’ve found they shoot line very well.

Tom: Kent, you also asked why we like to reverse the stripping guide. The configuration of the diagonal brace on a stripping guide is meant to add strength. I like to put the brace facing toward the front for two reasons. One, there’s no loss of strength doing it this way, and two, since it’s on the trailing side as line is going out, it doesn’t interfere with the line approaching from the reel end. Over the years, I’ve been asked,”why we put them on backwards.” My response is that there is no proper configuration; someone put them on forwards in the past, no one questioned it, and everyone else simply followed. I am not a follower.

Mark: I’m with Tom all the way on this. The anglers who notice the benefit of the way we orientate the stripping guides the most are those who shoot the most line. I’m talking about the two handed community. If you’re curious, you can video the running line going through a stripping guide during the final stage of a spey cast, then watch it in slow motion. As the thin running line hits the front guide, it often coils and wraps around the guide. When the stripping guide is orientated in the conventional way, you have more instances of the coil looping itself over the guide and interrupting the cast with a jolt, which often stops the cast short.

‘On Thread Wraps’

Kent: I know you said you use a three stage process for epoxying the thread wraps that attach the guides to the rod, whereas most rod manufacturers speed the process up, by doing it all in one coat. Can you please explain why you do it this way and how long it takes?

Tom: The epoxy on a wrap adds to the overall disturbance caused by weight, which we discussed earlier in relation to the rod guides themselves. That is why we use a very thin, lightweight epoxy and apply it, let it dry, carefully sand off any excess, then repeat steps two additional times. Doing it this way provides a nice flat result, as opposed to what I refer to as the football shaped epoxied thread wraps that you see on most other fly rods.

Mark: In terms of man hours it takes three times longer than just applying one coat, but you also have to factor in the drying time. The epoxy has to be totally dry before you can prepare the area for the next coat. So in real terms, it adds up to a week to the build time of a given rod (and also the time it takes us to repair a section of the rod). We think it’s worth it, both from the performance and aesthetic standpoint. Like a lot of the little details we focus upon, the extra effort adds cost and thus effects the price the angler is asked to pay for a Thomas & Thomas fly rod.

‘On Serial Numbers’

Kent: I noticed you still serial number every rod, as well as, every rod section. Can you shed light on the importance of this?

Tom: It is something we carried over from bamboo rod building. It only really helps in identifying the genera of a rod for repair, so that the spec’s can be retrieved from our archives, in the event that our designs and colors have changed since the rod was purchased. Thus, we can bring the rod back precisely to it’s original action and aesthetics. Beyond that, I personally think there is a “cool” factor. Fly fisherman and women love history. If someone inherits a rod or purchases a pre-owned rod, they’re often fascinated to hear about when the rod was made, who was working at T&T at the time, and who the original owner of the rod was.

‘On Crafsmanship’

Kent: Spending a day here at the T&T workshop, I’m excited at the prospect of sharing the experience with Gink & Gasoline readers. All day long I’ve been thinking to myself, this is what craftsmanship look like. What does it mean to T&T to craft rods in the USA?

Mark: In many fields of business today, craftsmanship is just a marketing buzzword, but at T&T, it really is a way of life. We’ve got Tom Dorsey and Tom Maxwell to thank for that. It means nothing less than a daily quest for perfection. We run a small crew of men and women that have been trained to accept nothing less, and besides, their pride wouldn’t let them. The average length of service of the rodmakers here at T&T is in the excess of twenty years. That’s twenty years of building rods over and over again, which produces superior levels of knowledge, skill and dexterity. We believe it shows in our final product.

Craftsmanship at Thomas & Thomas means rods built by a few talented individuals, working together toward the common goal of a structurally perfect fly rod. Doing it here in the USA means we can assemble a team that works and plays as part of the community of fly fishing. We are not separated by distance, language or culture from our market. In fact, we are part of our market. How could we consider delivering anything less than the best to our own community?

For more information about Thomas & Thomas fly rods and to watch videos of these fine fly rods being made, please visit their T&T website below.

Keep it Reel,

Come fish with us in the Bahamas!

Kent Klewein Gink & Gasoline www.ginkandgasoline.com hookups@ginkandgasoline.com Sign Up For Our Weekly Newsletter!

Thanks, what an engaging, well-written and touching story. I didn’t know most of that stuff, and I had no plans whatsoever of getting a T&T rod up until 10 minutes ago. 😉

couldn’t agree more here…all too often I leave this page with the overwhelming feeling that I “need” whatever you have just written about…great piece, thanks for sharing.

Jay,

Thank you for reading it and letting me know you enjoyed it. Have a great day my friend.

Kent

Oliver,

Glad you read today’s post. I know it was long but I strongly felt it all needed to be included. Especially since there’s lots of anglers out there that never were filled in on the full story. Glad to hear that the post sparked some interest in buying a T&T fly rod. They are superb rods built from passionate fly fishers.

Kent

Kent

Thanks for writing a terrfric post….long but very informative and for the true fly fishing angler a bit of history about a True American Company.A company that has seen the worst in the past but today has a bright future for hopfully many years to come.

I have worked in a shop and sold a lot of T&T’s in the Netherlands.

So I also had the joy to try a whole bunch of them. To me in craftmanship, it’s the best. They are also true fishing-rods, not merely casting units. I own an 8 weight Helix and did very well in a pikeflies casting match with a 10 weight Helix.

With a lot of wind they tend to lose a bit of feel, but overall I love my rod. It is great and in a.second and one false cast I cast from 6 feet on my left to 80 feet on the right. And vice versa. You can load the rod very progressively. Only downside is my new luxury problem; I won a Loop Cross S1 8 weight in a fishing match and can’t fish them at the same time 🙁

By the way, loved this article, even forgot to mention

Jasper,

Thanks for taking the time to read and comment on the post. T&T has always has my back and I’ll never forget it.

Kent

Great piece of literature… very well written and informative. Love this website… Keep up the great work!

Rob,

Thank you for taking the time to read this post. Please share to help spread the word about T&T’s bright future.

Kent

I visited T&T when I was on vacation with my parents back in ’81, I was 16. I dreamed of getting a T&T rod ever since. I purchased my own, 9′ 3wt, back in ’99. It is by far the finest piece of art I own. It is a beautiful thing to lay out 30 – 40′ of line to a rising trout on the South Holston river.

All I can say is Thank You, Thomas & Thomas. I will purchase again sometime in the near future.

Kent & Louis

Just a quick note on behalf of us all at Thomas & Thomas. It meant a lot to us that you both made the trip here to visit us. We really appreciate your heartfelt words regarding our endeavors and we thank you for yours. We’re pleased to see the success G&G is enjoying. You deserve it – fly fishing knowledge and passion in every post.

Best regards

Mark.

Mark,

Thank you for taking the time to comment on today’s post. We are very proud of how you and the rest of the T&T family have turned this wonderful fly rod company around. Congrats to everyone of you.

Kent

I own 3 TNT rods. Love them. This made me want to support them even more.

Michael,

Cheers to that my friend.

Kent

loved the article I own a great deal of T&T’s (over 30) I fish them all and will continue to purchase their product its so well made and i look forward to every new year to see what the team at T&T are doing next!

Yes, I too think it was a great piece of reporting. I own two T&T’s. My 4 wt LPS is my favorite rod. By the way, T&T is in my neck of the woods. If you come this way again, let me know and I’ll take you and my LPS fishing on the Swift!

Great news to read about the revival of Thomas & Thomas. I am the proud owner of an 8’6″ 5 weight T&T Vector which is easily my favorite trout rod. It’s just right and with all the feel you need when a fish is on. Perfect for the spate rivers of South Wales taking small wild browns and greyling, then dealing with a 5lb brownie from the Test. Magic. I look forward to the new range of T&T rods.

I have known Tom Dorsey for many years, after all he went to College Park. It was an honor and privilege to be on Tom’s guide staff. Quite simply he made the best fly rod in the industry and many of my clients would attest to that. I had not heard from T&T for many years, now I know why. Nor have I spoken to Tom since relocating to SW Florida 8 yrs ago. I was happy to see Tom was back with the Company, and wish him and T&T all the best. Needless to say when I am serious about catching a fish anywhere around the world, I carry my T&T rods.

A nice article! I am doing some research in search of T&T’s first rod shop here in Chambersburg, PA and have been corresponding with Tom Dorsey. The information you included has been helpful as well as an enjoyable read.

I sure enjoyed your article, but most of all I enjoyed reading about the re-emergence of T & T with it’s original craftsmen. I first learned about T & T rods from my guide buddies up on the Henry’s and South forks of the Snake River in Idaho. These are seasoned fisherman and they raved about the Horizon’s and the Vector’s. After talking one of them into letting me cast and fish a bit with his coveted Horizon I was really hooked. I’m 60 now & have fished since I was 3. My dad was a guide on Yellowstone Lake before there were outboard motors, and introduced me to fly fishing before I could fit into a pair of waders. In all that time I have never found a better rod than my 9′ 6 wt. Vector. That rod is a part of me now and is destined to be a family heirloom. I’d like to thank all of you at T & T for making this legacy possible for me. I threaten the kids that I’ll likely be buried with this rod, since I know there’s gotta be a few big trout in heaven. No doubt St. Peter will covet my Rod! Thanks fella’s!

Awesome write up and deep felt. I hope some day to visit the shop. I have a few older T&T rods. I have a HS 7 wt. with a loose reel seat I`m hoping I can get repaired.

I have one I picked up though that was made by Thomas D. with a story. Its a 10wt green blank with no name, a 63-227. It was given to a guy many years ago that is now in Maine as a wedding present. It was sad that he parted with it, and I even asked him to reconsider parting with it, but happy that I have it now displayed on a deer mount. I was gonna use it for salmon, but picked up a new T&T 10 wt. this year for that.

My favorite rod though is the fast TS 5 wt. I have. I have to say though the HS 4 wt. and that HS 7wt. have the feel of true works of art (as do they all). So glad T&T is still strong. Tight lines

That favorite rod is a NS, not a TS. Maybe that could get corrected by the moderator, thanks, Mike

Five years ago, my son and I toured the Thomas & Thomas plant…it was a wonderful experience…quality craftsmanship in manufacturing is still alive in the USA! I totally agree with Kent’s article. This type of quality craftsmanship is what made our country the economic power it is today. T&T is a perfect example of what’s great about American manufacturing.

As a dealer of classic fly rods for over 25 years I am continuously amazed that the T and T brand on the secondary market seems seriously depressed. There is nothing in your article that supports the rather poor performance of pricing for their bamboo on the secondary market. I have been a fan of the two Toms forever and truly feel that their rods should be valued much much higher. Their workmanship and consistency of quality control is above reproach; their bamboo rods are extraordinary for performance and appearance. Much more attention needs to be paid to the brand especially on the pre-owned market. Buy a T and T Individualist or Classic and you’ll understand the accolades.

Great article. I was introduced to the T&T NSII after winning the rod at the 2015 Ennis, MT Fly Fishing festival. I was fortunate to be able to try the rod on the Madison river the following week. Just a great rod I am going to treasure.

Excellent post, thanks for the history, I had no idea. I bought my fist TNT after try one that a fellow angler had. Now I own three!

Kent: Who sold the Thomas & Thomas fly rod company to that foreign group of investors?

I have owned three rods for over 20 years, love them. Broke one on a snook in Florida, sent it in for repair, can’t say enough about how go the service was. Glad the company is doing well, keep up the good work. Tight lines.

I have a Thomas and Thomas fly rod 9 foot 5 lb line but it also has markings on each individual piece saying 07 – 79 what does that mean and how much is a Rod worth it was given to me as a present and has never been used

I always enjoyed participating in the Pennsylvania Fly Casting Championship held at various locations around the Carlisle, Pa. area. I did not at the time own a 5 wt. rod that was required for the competition. I borrowed a friends T&T “Special Extra Dry” 8′ 2 pc. rod for the events and loved it! For years I tried to get him to put a price on the rod. Finally this year my wife and I moved to the Laurel Highlands in Pa. My friend asked what I was going to do with my lawn tractor and wagon….now the fun begins! After Paris Peace Talks type negotiations we struck a deal. I took the rod last weekend to Pine Creek and have to say that I had a lot more fun with the rod than I ever had with the Bolens! An email to John Carpenter at T&T with the serial number let me know that the rod was built in February 1993. I am delighted with the trade and believe it or not, my wife was fine with it.

I just located and purchased a T&T Special Dry Fly serial # G 4947. Could you tell me when the rod was built please? It is beautiful!! thank you. rod Cross

I just received a Thomas and Thomas es865, 8’6″ 5wgt.

I cant find any info on this, could you help.

Also, this is in Mint condition

While it’s evident you took great care in your writing and I applaud your credit to the current T&T staff, it is interesting that Tom Maxwell and all of his contributions were completely left out……the cursive trademark script, the T&T angler logo, the initial bamboo rod designs that gained T&T their notoriety all came directly from Maxwell. Not to take away from Dorsey’s contributions, it is unfair to leave Maxwell out. One might also say the true paradigm shift occurred when Dorsey pushed through his idea of creating a T&T board of directors and then influencing that board to force Maxwell out of the company in a power / money grab.